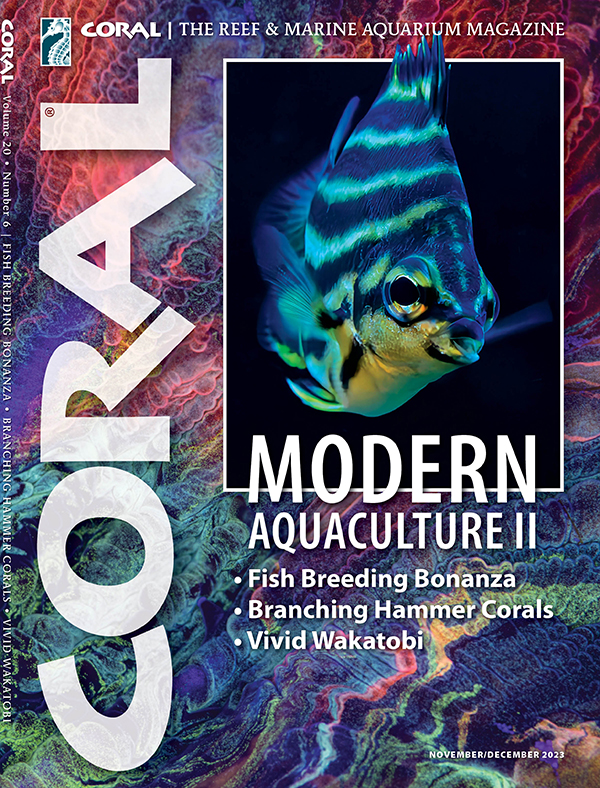

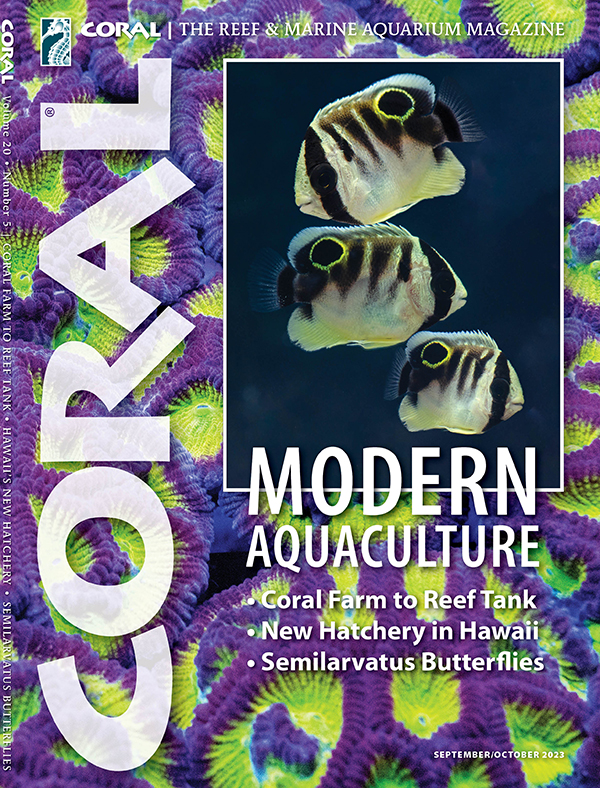

an exclusive CORAL Magazine excerpt from the September/October 2023 issue, Modern Aquaculture

Matt Pedersen interviews Chris Kiser, Stephen Barron, and Erin Pereira with images by EcoHarvest Hawaii. All images courtesy & copyright EcoHarvest Hawaii unless otherwise noted.

If you go west as far as you can on Hawaii’s Big Island you’ll find yourself on Keahole Point, just north of Kailua-Kona. There, starting in 1974, the State of Hawaii invested $130 million to create HOST Park, the Hawaii Ocean Science and Technology Park, operated by the National Energy Laboratory of Hawaii Authority (NELHA). The location is promoted by NELHA as “a unique outdoor demonstration site for emerging renewable energy, aquaculture, and other ocean-based sustainable technologies.”

A glance at a map reveals extremely close proximity to Kona International Airport, which translates to great air cargo service, a necessity for the aquarium trade. For those who follow the broader world of marine aquaculture, the area is home to highly recognizable companies including Cyanotech, producers of BioAstin Hawaiian Astaxanthin and Hawaiian Spirulina, and Blue Ocean Mariculture, developers of the noteworthy Kona Kanpachi (aquacultured Almaco Jack, Seriola rivoliana) which is marketed as being similar to Yellowtail and a truly sustainable dining option. HOST Park is also home to the Hawai‘i Island Kona branch of the Hawai‘i Small Business Development Center (SBDC) and offices of HATCH Blue, a worldwide venture capital group positioned as a global aquaculture accelerator. If California is home to Silicon Valley, it is looking like HOST Park may well be Hawaii’s Blue-Green Beacon, a literal hotspot and hub of marine aquaculture innovation.

This inviting Blue-Green Beacon has attracted a relatively new startup in the world of marine ornamental aquaculture: EcoHarvest Hawaii, LLC. Their secure compound is situated adjacent to a coastline of lava rock, grass, and trees, with the Pacific Ocean completing the scene. Within the confines of this relatively small space, three unique individuals from different walks of life have joined forces to meet the needs of the marine aquarium industry at a scale not yet seen within the trade. Their first shipments of aquacultured Centropyge angelfish have just been completed to select wholesalers and aquarium retailers in the U.S. and Europe, and this is just the start. CORAL Magazine’s Matt Pedersen met with the team to discuss their big plans on the Big Island.

CORAL: Let’s start by getting to know everyone here today. Chris, do you want to start?

Chris Kiser (CK): I’m the founder and COO at EcoHarvest. What got me into aquaculture and fish to begin with? I was about 6 years old and in the middle of North Carolina, nowhere near the ocean. I was lucky that the pet store in town had an amazing saltwater section, which was unusual back then. My mom would drop me off there and I’d stay for hours and just stare. That’s what made me fall in love with marine biology—aquariums. So I studied marine biology in college, and got into aquaculture in the summers. After college, I started working with warmwater marine finfish in the Florida Keys, and we were one of the first hatcheries to commercially scale Mutton Snapper and Cobia. That success took me down to Belize, where we built what was, at the time, the largest warmwater marine fish hatchery in the Americas. I’ve always enjoyed being on the pioneering edge of the aquaculture industry. It’s not salmon farming, not big business, but trying to establish commercial viability for new species. I’ve always come back to ornamentals. It has been a hobby of mine since I was 10-years old, and I have had an aquarium in my home ever since. I’ve always wanted to culture ornamental fish, but there was always too many bottlenecks. There’s something in me that wants to do the hard thing, the thing that’s not being done. When I saw the early successes people were having with angelfish, then the team at OI (Oceanic Institute at Hawaii Pacific University) with tangs a few years ago, it all just started coming together. Many of those early bottlenecks were being removed. I was at a spot in my career where I was ready to try to branch out and start my own company. That’s what led me to start EcoHarvest.

Stephen Barron (SB): I’m the CEO of the company. My background is not in marine bio, but was Wall Street commodity trading. My passion and why I’m pursuing this venture goes back to my days as an aquarist, having multiple tanks and reef tanks in my home. I scuba dive, I fish, and I’m an avid lover of the oceans. I see an opportunity here. Chris and I speak quite a bit about looking at ornamental fish; obviously they’re a higher-dollar species to work with in terms of aquaculture. There’s an ability to sustain ourselves economically by participating in this industry.

CORAL: So how did you two come together to start EcoHarvest?

SB: Chris and I first came together because I was working in Texas on a RAS (recirculating aquaculture system) steelhead trout farm. After my commodity days, I came back to Texas and I invested in a food fish brokerage company with a friend. So, I was getting more into aquaculture and had a better understanding of the seafood industry. I was looking at different agriculture and aquaculture opportunities and the whole RAS opportunity was hot. RAS was a giant fish tank, basically. I spent years learning about the systems—Chris and I both did. We learned a lot during that process.

I spoke to a lot of people. I needed the right partner for this RAS project. I needed to find someone who had the knowledge of how to grow fish, but at the same time also had a commercial background, someone who was practical, and someone who could deal with managing 50 people. I went through LinkedIn, and talked to a number of people, I found Chris, went out to see him, and now we’re going along 3–4 years later with EcoHarvest.

CK: I started working with Steve when I living in Hawaii. He contacted me through networking to assist with the development of the RAS trout farm in Texas. So, I was basically working with Steve and we’d talk every day about developing the trout farm, the ins and out of getting that going.

SB: I think of how we switched so quickly into this aquarium business: We looked at giant development projects in the food fish industry where you might have a 60-million dollar investment, and then we looked at doing this in the ornamental trade and were able to pivot. Finding Erin is a story as well. I asked, “Do you know anything about Yellow Tang,” and Chris hadn’t worked with them. So we networked. We talked to a number of people, came across a friend of hers, and wow…we found someone who’s actually done Yellow Tangs!

CORAL: A perfect segue. Erin, explain your background and how you came to be the third crucial part of the EcoHarvest team.

Erin Pereira (EP): I’m the Sr. Hatchery Manager. I spent my college years trying to hide a massive coral tank in my dorm room. I became interested in ornamental aquaculture when I got a job at a local aquarium. I started taking note of how hard it is to take care of some fish, particularly when they first arrive. That posed the question, “If we’re having these issues, why aren’t we getting them cultured like freshwater fish?” That’s when I first learned that very few marine fish were being cultured at the time. At that point, I formed my career goals around the idea that I needed to be a part of making aquacultured marine aquarium fish a commercial reality.

I was getting ready to graduate with my undergrad degree in Florida, and had one of my professors actually tell me I’d never get into aquaculture, but I eventually convinced Chad Callan to accept me as his graduate student at OI. It was great to really learn and do those things [like breeding Yellow Tangs] at research setting and contributing to peer-reviewed literature, but I’ve always had this sense that there’s no reason to research something if we’re not going to scale it into industry.

After graduate school I spent some time in the wholesale aquarium trade hoping to have an impact on improving care and handling. I realized there was even greater need for aquaculture, and that ultimately my career focus needed to stay with aquaculture. After I left wholesale and was moving back to Hawaii, a mutual contact from my time at OI said, “I know some guys who might be thinking about Yellow Tang.” I met Steve and Chris and really aligned with what they’re trying to do, and think that the opportunity is now.

I’ve been really happy with being part of the team at EcoHarvest because it’s a perfect trifecta of experience that blends together really well. Chris has this diverse commercial aquaculture background, and can say “If we want to produce 2 million fish, let’s back calculate to figure out how big copepod systems need to be.” Then there’s Steve, talking about how we project ourselves, how we plan for the future. And I’m the one that has practical experience with ornamentals, who more or less can tell you what a Yellow Tang egg looks like and what to expect during their difficult rearing process. I remember the first egg we got, and I had it on the tip of my finger. I ran across the farm like a crazy person to show Chris. How do we turn that one egg into hundreds and hundreds of thousands?

CORAL: I think this gets to the heart of what EcoHarvest envisions. What’s the goal?

CK: Our goal is to create a consistent supply of ornamental fish into the hobby that’s aquacultured instead of wild-caught, and to become an alternative to as much of that wild-caught fishery as possible.

SB: Where we’re a little different [from existing ornamental aquaculture companies] is we’re trying to do this at a commercial scale. We’re not the pioneers, the first to do these species, but we want to be the first to do it at scale. We’re not shooting to provide 50,000 fish in a year. We want to be able to address the industry demand and produce upwards of a million fish per year. To do that, it’s a different type of operation than I know that exists today. Our end goal is to produce enough fish that our cost of production allows people to purchase an aquacultured fish at the same price as a wild-caught fish.

EP: When we’re choosing our species, we’re pulling from the bread and butter, the first semi-expensive fish that you buy, like a Coral Beauty. We’re looking at fish that have a high demand, that aren’t necessarily high-end, thousand-dollar fish. We’re looking at sub-$100 retail. We’re looking at what the data is telling us to buy, what is being collected at that volume, and how many units we have to produce.

CORAL: There are people who think that trying to increase the presence of aquacultured fish in the aquarium trade is meant to bring an end to wild fisheries, even when they’re sustainable. What would you say to that?

CK: You get the same sort of reactions in food fish as well. We’re not out to target or stop the wild fisheries. We want to offer a more sustainable option, and let the consumer decide. But what I think that you’re going to see is regardless of whether we farm them or not, in a lot of areas where these fish are collected, it’s done in an unsustainable way, and it’s going to end whether we want it to or not. It could happen either due to overfishing, regulatory action, or just ecosystem collapse as a result of larger factors. Look at what is happening to Florida’s coral reefs this summer. So, whether someone like us comes in and offers and alternative or not, you’re looking at something [a fishery] that has an expiration date. I think there are sustainable fisheries out there. Hawaii was one, and it got shut down anyway because of activism. Even if you are doing it the right way, your wild fisheries are in jeopardy. We have to be the alternative.

CORAL: Relating to this, it came up in our conversation that you don’t like the term “captive-bred” for the fish you produce. Why?

CK: Well, it’s not that I don’t like it myself, we’ve just found when telling our story that term “captive” doesn’t resonate very well with people. People that have an issue with animals being kept in captivity obviously those people aren’t going to have aquariums to begin with, but it gives them ammunition to use in arguments against the industry. “Captive-bred” is a term that the hobby coined, and I’ve used it for a long time, but someone mentioned that’s probably not the best way to say it. There are plenty of other ways to say a fish wasn’t collected in the wild.

EP: In the current climate, when we’re trying to get people not in the hobby to believe in what we’re doing in and buy in, what we’ve encountered is when you start with “captive-bred” it opens the door for critique. “What do you mean, you’re housing animals… wouldn’t it be easier to not have animals in captivity altogether?” They’re not thinking, “Oh, you’re doing this great thing that’s going to reduce pressure on wild population.” So we’re looking for a better way to get buy-in from the layman.

SB: “Captive-bred” is associated with the aquarium industry being about pets. I don’t see it that way. Any marine hobbyist will tell you a marine aquarium is not just a pet. It doesn’t exist without a lot of care, a lot of work, and a lot of knowledge. It’s an environment you truly have to care for and have a passion for. It’s a learning tool. It’s a science project in your house. How many people learn tremendous science from aquariums? Everything from the nitrification process, ammonia removal, what all the filters do; those are amazing things to learn. So, it’s an aquarium hobby, not just about a fish and “my pet”, it’s a learning tool. People are more likely to resonate with that.

EP: When thinking about aquariums, I’ve always wondered should we have them or should we not? People don’t care about what they can’t see and can’t access. So from a conservation standpoint, how do you get that kid in Kansas to care about reef restoration? Keeping aquariums inspires stewardship and brings up the next generation so that land-locked kid can have the ability to understand the ocean.

CORAL: In the same way, you’ve noted there are issues with the term “ornamental” aquaculture?

CK: On the business side for us, if you say you’re in ornamental aquaculture? “Oh well you’re just a hobby, you’re not a real business.” We’ve run into that when we’re out looking for investment. No, we’re an aquaculture company, but we just so happen to work with ornamentals. We’re not doing this out of my basement either.

CORAL: So how is EcoHarvest different? How is it going to silence those who write you off as just another “ornamental” hatchery?

SB: We knew from the get-go that to scale an operation to the size we desire, we need to find some novel ways of doing things, otherwise it’s going to get too expensive. So we worked on the overall design. There are just four people running this entire operation.

CK: Working in fish hatcheries for much of my career, there are a lot of inefficiencies. I see a lot of opportunities to use automation and machine learning to make a lot of these processes less labor intensive, but also to optimize the environment for the fish to get better survival and better yields. For example, a hatchery our size would usually have two people to just grow microalgae, just to maintain enough feed stock for the copepods. We’re probably doing it with just “half a person” in terms of labor-hours [reducing labor by 75%].

A big problem with scaling the ornamental species we work with is the requirement for live algae in the production chain. We will probably end up needing to use tens of thousands of liters of live algae per day. I ran one of the largest algae farms in the world for eight years, so we know how to easily scale cultivation to that size that is feasible and not intimidating.

EP: Chris and I try to reduce the number of buckets we carry. We have designed a hatchery that makes it easier. It’s important to note that the hatchery we have now is our proof-of-concept hatchery.

CK: So this is our pilot hatchery, we’re learning as we go along. What we think may work, we may find out it doesn’t, so we try new things, and sometimes those things may work. We’re not trying to reinvent the wheel. We tried the wheel first. But there are certain things that when we want to scale something 50 times its current size, it’s not going to work.

EP: This keeps us from going on these trails that aren’t going to lead to commercial viability. We’re definitely not following the exact recipe that’s shown to be replicable across multiple species. Rather than apply that original recipe, we’re deviating from that with a purpose and a roadmap. When we think how many pelagic fish are actually going into the market each month, total combined Centropyge and Tangs, how many thousands is that? To me, when the demand is in the hundred thousands, but only a few thousand aquacultured fish are being produced, that’s what I call boutique scale. For us, we’re thinking we need 10,000 each month, then scale to a million each year. I remember trying to scale up rotifers earlier in my career, and the question was how many Home Depot buckets do we need? Now, it’s how many swimming pools do we need?

CORAL: So where are you at today, right now?

SB: We’re selling fish right now into a few markets. We’re selling direct to retailers, and selling to some wholesalers as well, in multiple locations in the U.S. and Europe.

CK: To be realistic, we have this cohort of fish going out, and then we’re going to have probably a 5-month gap, because we had typical startup pains. November is our goal for additional supplies for sale, at which point we’ll be at a couple thousand fish per month. And we need to have some consistency behind that. We’re making progress. When we stocked the Coral Beauty eggs, we were averaging 1,000 to 1,500 eggs per day around December 2022. Our average egg production right now is about 12,000 eggs per day. Our egg production is exponentially higher now, and still going up. This pilot facility is designed to do 4,000 fish per month.

CORAL: So you’re really just getting started but there are big plans.

EP: People can expect a lot more diversity in the pygmy angels. It will start with a good selection of staple fish, particularly Coral Beauties (Centropyge bispinosa) and Flame Angels (C. loriculus). We’re also making progress with Bicolor Angels (C. bicolor), Multicolor Angels (C. multicolor), and the Fiji Blue Velvet Angel (C. deborae). And we’re still working on the Yellow Tangs (Zebrasoma flavescens) and Blue Tangs (Paracanthurus hepatus).

SB: We’re looking to add additional broodstock species, but we wanted to resolve some of our initial issues. By the time someone is reading this, we’ll have more. We can bring most non-endemic species into Hawaii to raise them.

CORAL: What will EcoHarvest’s growth entail?

SB: So, we’ve had three rounds of capital raising to date. We’ve had angel investors. We’ve had different friends and family rounds of investment. We actually have a fund investor, HATCH BLUE; we’re in their accelerator program. They’re very important; they’re people who promote innovative thought within the seafood and aquaculture space. Knowing that we need to find new ways and change, they’re attracted to us because of our innovation and efficiency. We’re investment-ready at the same time, using unique methods and technologies.

To expand, we’ll need additional investors to help with some of the capital, but hopefully we’ll have our own revenue streams shortly to keep our operation going on our own. We’re talking millions of dollars to build it out to the scale that we’re interested in getting to.

CORAL: And what will that look like?

SB: If we go to 50 species, all depending on broodstock performance, obviously we’re going to have to expand. Ultimately we’re going to need several acres for the facility. Right now we’re completely outdoors; we’re going to need more indoor space to protect larval rearing, to control conditions better. That’s part of our goal.

EP: In the past, you have two or three groups of broodstock, when they give you eggs, you do a run. We want to have hundreds of thousands of eggs every day, so that’s a hangar full of broodstock and we’re starting new larval runs every day. When we have a full-scale farm, there will be groups of people who just work in broodstock or copepods. Right now, we’re really great at packing in a lot of usable space in a small footprint. Our workspace is about two people wide, but we can do everything we need to do. Every square foot we build has a purpose and is planned.

CK: All of our plans, projections, it’s all based on the current industry numbers that are happening right now. What we don’t factor in—if we’re successful doing everything we say—is dramatically expanding the marine aquarium hobby.

Right now, a lot of people stay out of marine aquariums because they cost too much; bottom line, they’re way more expensive than a freshwater tank. If we scale to the point where you can get some of these fish down to $20 in a pet store, all of a sudden it opens doors to people that can start considering getting into the hobby when they couldn’t have before. We could have that impact 5–6 years from now.

SP: This is a very price sensitive world. Costs change dramatically with volume. When we bring prices down, more purchases are made. It’s a shame, it’s the kids asking their parents, “Buy me a $1000 fish tank?” If we can reduce that price for someone to get the marine aquarium experience that would be a great goal to have.

I was just at the Shedd Aquarium (in Chicago, Illinois). The buzz in there was amazing. There’s so much life, good feelings, fascinated people. Certainly, there are people who are never going to like the aquarium hobby, but they’re not seeing it for what it really is. People’s minds are activated, aquariums are very engaging, and I’ve loved them since I was a kid. Things would get kind of boring if aquariums weren’t in our lives.

If you enjoyed this story, then you definitely won’t want to miss the next installment in our Modern Aquaculture duology, MODERN AQUACULTURE II. Subscribe to CORAL Magazine before October 10th to start with this forthcoming new issue of CORAL Magazine!